The bending properties of steel versus stainless steel

The Bending Properties of Steel (Carbon Steel) Compared to Stainless Steel (SS)

The bending properties of steel (carbon steel) versus stainless steel (SS) differ in several ways, including strength, elasticity, and response to loads. Here are the key comparisons:

Modulus of Elasticity

-

Steel (Carbon Steel): The modulus of elasticity of carbon steel is about 210 GPa. This means carbon steel has high stiffness and deforms less under load.

-

Stainless Steel (SS): The modulus of elasticity of stainless steel is slightly lower, around 190–200 GPa depending on the alloy. This means stainless steel is a bit more flexible than carbon steel.

Tensile Strength and Yield Strength

-

Steel (Carbon Steel): Carbon steel generally has lower tensile and yield strength compared to stainless steel. Depending on specification and treatment, tensile strength typically ranges from 400–600 MPa, with yield strength around 250–400 MPa.

-

Stainless Steel (SS): Stainless steel offers higher tensile and yield strength. For common grades like 304 or 316, tensile strength ranges from 515–860 MPa and yield strength from 205–450 MPa. This means stainless steel can withstand more load before deforming or breaking.

Bending Strength

-

Steel (Carbon Steel): Carbon steel bends well and is relatively ductile, meaning it can deform without breaking. This makes it suitable for many structural and industrial applications.

-

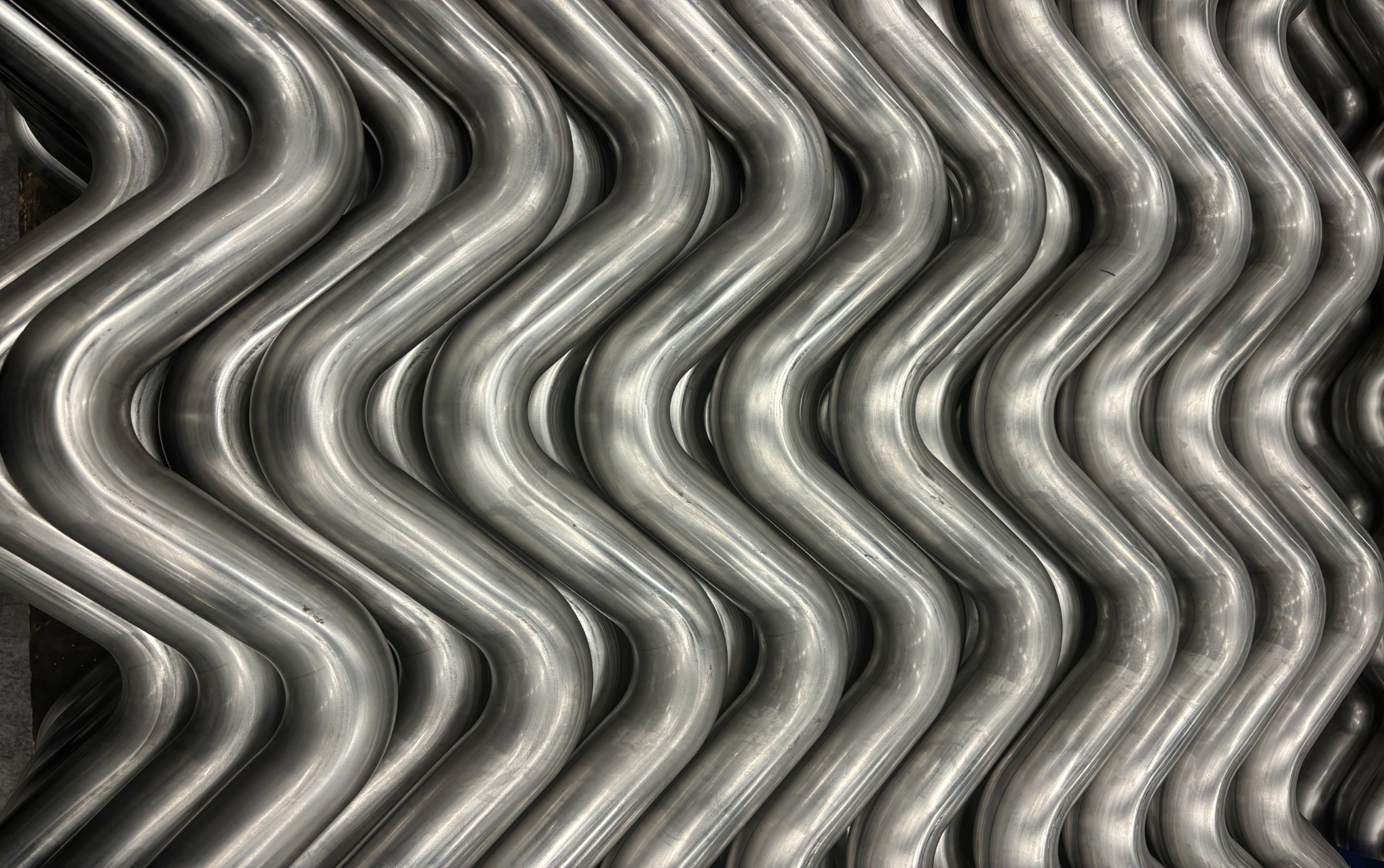

Stainless Steel (SS): While also ductile, stainless steel has higher bending strength due to its greater tensile and yield strength. More force is required to bend stainless steel compared to carbon steel.

Fatigue Resistance

-

Steel (Carbon Steel): Carbon steel has reasonable fatigue resistance but is more prone to fatigue cracks and corrosion under cyclic loading if not properly protected.

-

Stainless Steel (SS): Stainless steel generally has better fatigue resistance, especially in corrosive environments. This is due to its corrosion resistance combined with higher tensile strength.

Corrosion Resistance and Maintenance

-

Steel (Carbon Steel): Carbon steel is susceptible to corrosion and rust, which can affect bending properties and structural integrity over time. Regular maintenance and protective coatings are necessary to extend its lifespan.

-

Stainless Steel (SS): Stainless steel is highly corrosion-resistant, maintaining its bending properties and structural integrity in corrosive environments without requiring much maintenance.

Applications

-

Steel (Carbon Steel): Commonly used in construction, automotive, and other applications where high strength and ductility are important, provided protective measures against corrosion are applied.

-

Stainless Steel (SS): Often used in medical equipment, food processing, architectural applications, and other environments where both high strength and corrosion resistance are required.

Conclusion

The choice between carbon steel and stainless steel depends on the specific application requirements. Carbon steel is generally more cost-effective and easier to work with but requires corrosion protection. Stainless steel offers superior performance in terms of tensile strength, bending strength, and corrosion resistance, making it more suitable for demanding environments.